Latest Trends in Industrial Robots: Insights from Australia

The Rise of Industrial Robots in Australia

In recent years, the integration of industrial robots has dramatically transformed the manufacturing landscape in Australia. This shift is driven by various factors, including the need to enhance productivity, improve precision, and reduce operational costs. As industries strive to maintain competitive edges in a global market, the adoption of robotic technologies is becoming increasingly prevalent.

Industrial robots are no longer confined to large-scale operations; they are now accessible to small and medium enterprises (SMEs), allowing them to compete with bigger players. This democratization of technology is vital for the sustainability and growth of the manufacturing sector in Australia.

Advanced Robotics Applications

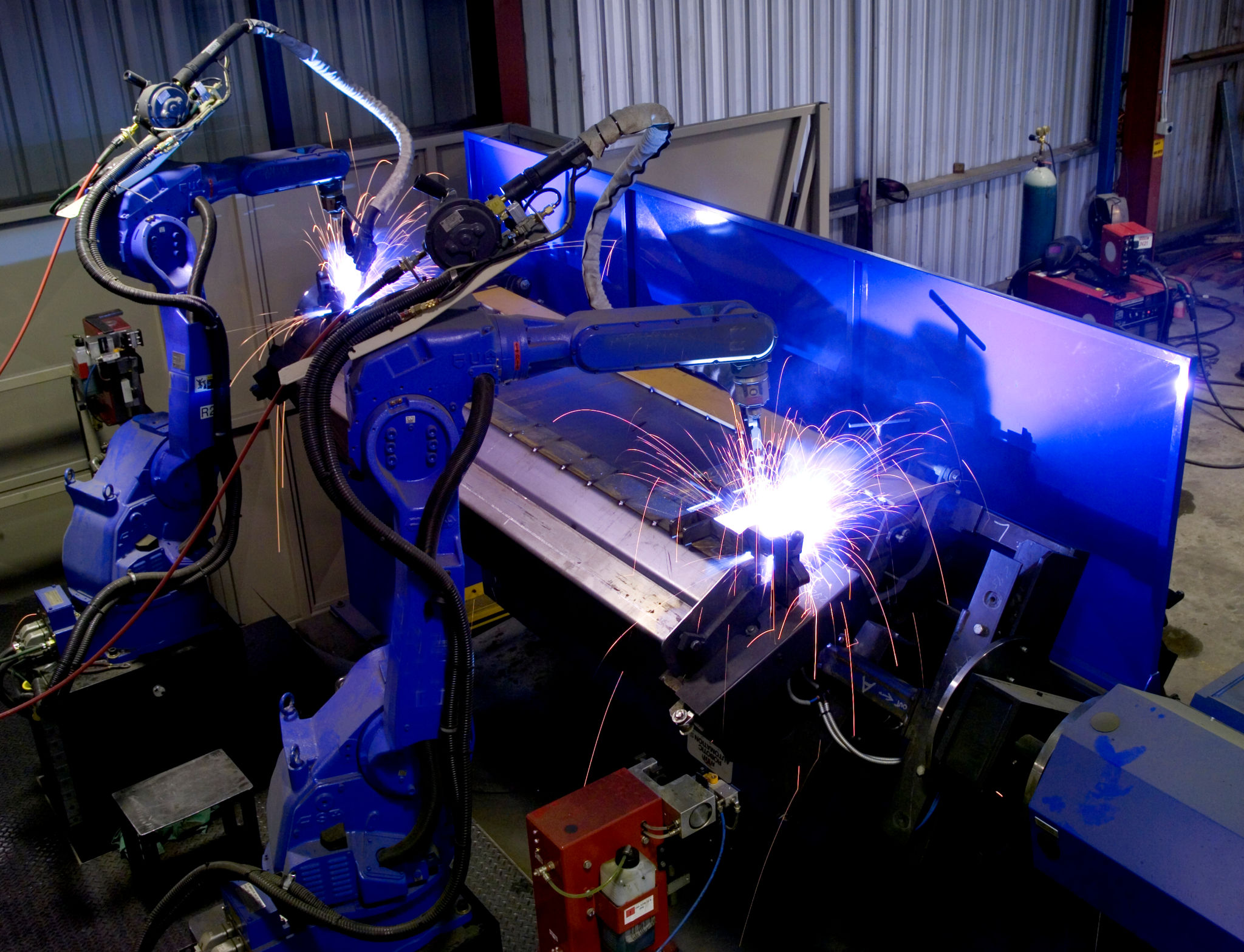

One of the latest trends in the industrial robotics sector is the use of advanced applications like collaborative robots, or cobots. These robots are designed to work alongside human employees, enhancing productivity while ensuring safety. Cobots are equipped with sensors and AI capabilities that allow them to perform complex tasks with precision and efficiency.

Moreover, industries such as automotive, electronics, and food processing are increasingly utilizing robotic automation to optimize their operations. From assembly lines to packaging, the versatility of industrial robots is proving invaluable in streamlining processes and reducing error rates.

Integration of Artificial Intelligence

The integration of Artificial Intelligence (AI) with industrial robots is another significant trend that is shaping the future of manufacturing in Australia. AI-powered robots can learn from their environments and adapt to new tasks without extensive reprogramming. This capability is particularly beneficial in dynamic production environments where flexibility and adaptability are crucial.

With AI, robots can perform predictive maintenance, reducing downtime and prolonging equipment life. This technological advancement not only enhances operational efficiency but also minimizes costs associated with repairs and replacements.

Challenges and Opportunities

Despite the promising advancements, there are challenges that industries face when adopting industrial robots. The initial cost of investment can be high, and there is a need for skilled personnel to manage and maintain these technologies. However, the long-term benefits often outweigh these initial hurdles, offering substantial returns on investment.

- High initial investment costs

- Need for skilled workforce

- Integration with existing systems

Opportunities abound for industries willing to embrace these challenges. By investing in training programs and fostering a culture of innovation, businesses can leverage the full potential of industrial robotics to drive growth and competitiveness.

The Future of Robotics in Australia

Looking ahead, the future of industrial robots in Australia seems promising. Government initiatives aimed at promoting technological advancements and fostering innovation are likely to play a pivotal role in this journey. Moreover, as more industries realize the benefits of robotic automation, we can expect a surge in demand for these technologies across various sectors.

In conclusion, the landscape of industrial robotics in Australia is evolving rapidly. By staying abreast of these trends and investing in cutting-edge technologies, Australian industries can look forward to a future where efficiency and innovation go hand in hand.